1300 cross flow drag/chopper trike

-

adamparrott

- Member

- Posts: 178

- Joined: Sun Jan 20, 2013 3:50 pm

- Location: Romford Essex

Re: 1300 cross flow drag/chopper trike

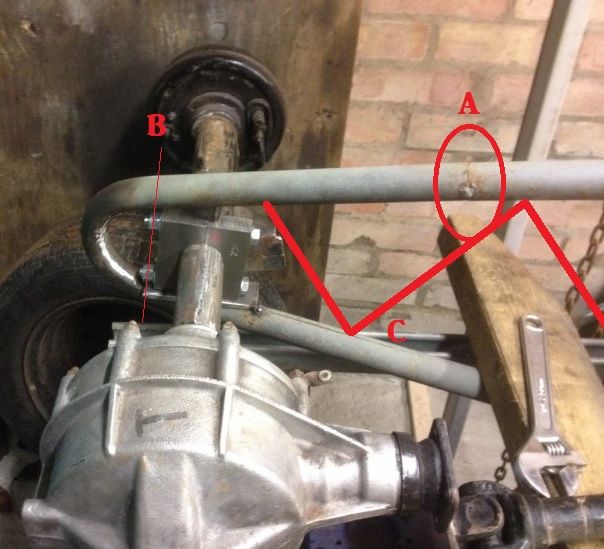

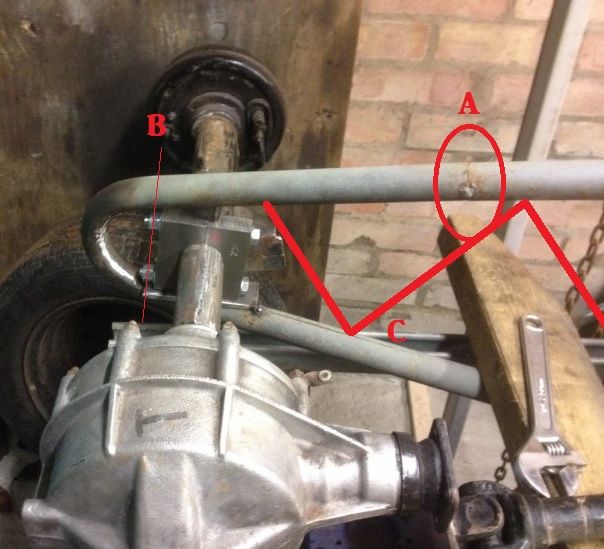

Got my axle mounts, fits lovely just thinking of the best way to fit them bit stuck on how to do so  anyone got any ideas. I'm thinking of making a plate for it to sit in within the u bend. But I'm worried it will look weird. Bearing in mind this is the first time Iv built a trike.

anyone got any ideas. I'm thinking of making a plate for it to sit in within the u bend. But I'm worried it will look weird. Bearing in mind this is the first time Iv built a trike.

You do not have the required permissions to view the files attached to this post.

- VmaxRik

- Moved in and now we can't get rid

- Posts: 7293

- Joined: Mon Jul 18, 2011 3:47 pm

- Location: Scunthorpe

- Contact:

Re: 1300 cross flow drag/chopper trike

Nice substantial pieces of kit....makes a nice change from some we've seen.

To mount the axle properly, those plates need to be fitted as near to where the old leaf springs lived as possible. If you fit them inboard as you've shown, the axle torque tubes and half shafts will bend just for something to do....it's an oft made mistake and one that needs addressing in the build stage.

Hope this helps.

To mount the axle properly, those plates need to be fitted as near to where the old leaf springs lived as possible. If you fit them inboard as you've shown, the axle torque tubes and half shafts will bend just for something to do....it's an oft made mistake and one that needs addressing in the build stage.

Hope this helps.

This nation wasn't given to our forefathers, it was wrought over a 1000 years of bloody war and the efforts of those who came before.

Let it not be us who bears the sin, of giving it away to the enemy within.

Let it not be us who bears the sin, of giving it away to the enemy within.

- gtr-trike

- Part of the Furniture

- Posts: 929

- Joined: Sun Nov 28, 2010 2:08 pm

- Location: Devonshire

- Contact:

Re: 1300 cross flow drag/chopper trike

as Rik says, mount the axle as far outboard as possible, as smart and tidy as the back of that frame is, youve really made life hard for yourself LOL, theres a reason why people like me finish the back of a frame parallel in both axis and open at the rear, easy to weld in mounts like you have there, same as mine basically 1" steel bored 2" and split with 12.5mm holes through.

far easier to mount the axle into the frame from the rear

and as good and solid as those mounting plate are, they are now only going to be as good as the mounts you make from the frame to them.

the nice bend really is smart, are the back parts of the frame parallel to each other or do they point inwards towards the front?

far easier to mount the axle into the frame from the rear

and as good and solid as those mounting plate are, they are now only going to be as good as the mounts you make from the frame to them.

the nice bend really is smart, are the back parts of the frame parallel to each other or do they point inwards towards the front?

- gtr-trike

- Part of the Furniture

- Posts: 929

- Joined: Sun Nov 28, 2010 2:08 pm

- Location: Devonshire

- Contact:

Re: 1300 cross flow drag/chopper trike

you also need to get some serious triangulation into the middle area of that frame, one bump and it fold in half :(

-

adamparrott

- Member

- Posts: 178

- Joined: Sun Jan 20, 2013 3:50 pm

- Location: Romford Essex

Re: 1300 cross flow drag/chopper trike

I find to make thing hard for my self. Iv got some more pics as

As for the bends they run inwards towards the middle of the frame Iv got more frame work todo and lots of scratching my ass. I will put up a pic of the frame running inwards for you Gtr....

As for mounting the axle this is the most I can go towards where the springs were this would be half way on the shaft.

This is only mocked up at the moment with spot welds as I'm not 100% on how to do this yet.

As for the bends they run inwards towards the middle of the frame Iv got more frame work todo and lots of scratching my ass. I will put up a pic of the frame running inwards for you Gtr....

As for mounting the axle this is the most I can go towards where the springs were this would be half way on the shaft.

This is only mocked up at the moment with spot welds as I'm not 100% on how to do this yet.

You do not have the required permissions to view the files attached to this post.

-

minimutly

- Part of the Furniture

- Posts: 769

- Joined: Sun Feb 09, 2014 5:28 pm

- Location: west wales

Re: 1300 cross flow drag/chopper trike

Adamparot, it will bend the axle.

Btdt, best to fix it now, remake the frame, move them out.

All the best,

Huw

Btdt, best to fix it now, remake the frame, move them out.

All the best,

Huw

-

adamparrott

- Member

- Posts: 178

- Joined: Sun Jan 20, 2013 3:50 pm

- Location: Romford Essex

Re: 1300 cross flow drag/chopper trike

Thanks for the heads up minimutly, i have taken into account with bending the axle, i have strengthened the axle already by putting angle onto the axle beam thick enough so it won't bend, i had a mate of mine to look at this and he said it will be ok as its been strengthened in the right (he say's). aswell this axle has previously been on another trike with the same position as the last frame was mounted on. i have also made brackets off the angle for the hand brake cables. hopefully this will work out nicely.minimutly wrote:Adamparot, it will bend the axle.

Btdt, best to fix it now, remake the frame, move them out.

All the best,

Huw

- Doc.

- Moved in and now we can't get rid

- Posts: 1942

- Joined: Sun Nov 22, 2009 1:12 pm

- Location: South BUCKS

1300 cross flow drag/chopper trike

I'll add a couple of things Adam.

The angle sections you've added will stiffen it up, but like the others, I think it needs a bit more support.

You could add a couple of 'struts' on the top, welded to the frame rails, bolted to the axle tabs.

It wouldn't make it untidy, something like this . . .

Also, as GTR mentioned, the frame sections need some triangulation (C), thing is, to do it properly, you're going to box-in the axle, making it impossible to remove without completely disassembling the axle itself (Tubes removed from Diff), which would be impractical.

I'd suggest, like others have, that you have it removable from the rear.

I like the bends at the back, very neat as others have said, you could keep that feature by slicing the bends off, and making them part of the rear half of the clamps. (B)

Keep it neat, cap the cut ends with steel sheet, and you won't notice the join.

Lastly, is (A) a butt joint?

If it is, have you sleeved it internally (smaller tube inside)?

The angle sections you've added will stiffen it up, but like the others, I think it needs a bit more support.

You could add a couple of 'struts' on the top, welded to the frame rails, bolted to the axle tabs.

It wouldn't make it untidy, something like this . . .

Also, as GTR mentioned, the frame sections need some triangulation (C), thing is, to do it properly, you're going to box-in the axle, making it impossible to remove without completely disassembling the axle itself (Tubes removed from Diff), which would be impractical.

I'd suggest, like others have, that you have it removable from the rear.

I like the bends at the back, very neat as others have said, you could keep that feature by slicing the bends off, and making them part of the rear half of the clamps. (B)

Keep it neat, cap the cut ends with steel sheet, and you won't notice the join.

Lastly, is (A) a butt joint?

If it is, have you sleeved it internally (smaller tube inside)?

-

minimutly

- Part of the Furniture

- Posts: 769

- Joined: Sun Feb 09, 2014 5:28 pm

- Location: west wales

Re: 1300 cross flow drag/chopper trike

All good advice, nice to hear you're thinking about it. My own trike had the axle mounted too far in, it wasn't removable, and it was bent. sh!t design. And it's not just the tube outside the mountings that can bend, the diff casing is just soft cast alloy, not designed to accept bending forces at the flanges.

The "T" at the top of the diff made me laugh, I made new tubes, welded new hub flanges, made the brackets, welded etc. then had the horrible thought - is it the right way up??

Huw

The "T" at the top of the diff made me laugh, I made new tubes, welded new hub flanges, made the brackets, welded etc. then had the horrible thought - is it the right way up??

Huw

-

adamparrott

- Member

- Posts: 178

- Joined: Sun Jan 20, 2013 3:50 pm

- Location: Romford Essex

Re: 1300 cross flow drag/chopper trike

Thanks for you input Doc. i have taken in a lot of advice and at this stage it's really important. now to answer the question's.Doc. wrote:I'll add a couple of things Adam.

The angle sections you've added will stiffen it up, but like the others, I think it needs a bit more support.

You could add a couple of 'struts' on the top, welded to the frame rails, bolted to the axle tabs.

It wouldn't make it untidy, something like this . . .

Also, as GTR mentioned, the frame sections need some triangulation (C), thing is, to do it properly, you're going to box-in the axle, making it impossible to remove without completely disassembling the axle itself (Tubes removed from Diff), which would be impractical.

I'd suggest, like others have, that you have it removable from the rear.

I like the bends at the back, very neat as others have said, you could keep that feature by slicing the bends off, and making them part of the rear half of the clamps. (B)

Keep it neat, cap the cut ends with steel sheet, and you won't notice the join.

Lastly, is (A) a butt joint?

If it is, have you sleeved it internally (smaller tube inside)?

(A) There is a internal tube 3mm wall inserted tightly for support. about 1ft long this i have put in all my joins.

(B) i've wanted to keep the bends on the back but i'm in a position of not knowing what to do with them completely. at this stage i can move the axle back a little more. im thinking of making a plate for the rear axle mount to fit onto the frame curve and for when i need to remove the axle it will be a straightforward job of moving it forward a little and then out sideways through the frame. thats if im on the same wavelength as you.

(C) there will be triangulation in there something like what you have shown in the picture, but i'm going to make it just the right amount of room for when the axle does have to come out there will be room. basicly just where the letter (C) is that is where it will start. the reason nothing is there yet is just so i know where everything is going and in the event of removing axle or anything like that it can be done easily without swearing.

I know i'm doing this in a strange way but i dont want to go back and redo framework. i have a lot of